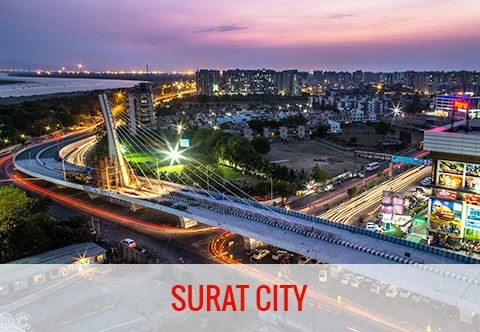

Silk city surat

Know Your City:SILK CITY SURAT From home-based businesses to busy markets, how Surat’s textile industry has evolved since 1970s

Silk city surat Busy traffic of trucks and mini-trucks loading and unloading textile bales and finished goods keeps Surat’s Ring Road abuzz. The oldest among the textile markets here is the Surat Textile Market (STM), inaugurated on Vijaya Dashami in October 1972 by Morarji Desai, the MP who went on to become the prime minister.

Harbanslal Arora, 65, the STM’s acting president who is from Sonepat in Haryana and opened his shop in 1978, recalls how Desai had warned in his speech that the textile business would soon be dominated by “outsiders”. He adds that Desai’s words have come true.

Silk city surat Textile traders of Surat, known for its man-made yarns and brocade industry, would run their businesses from their homes before the seventies. The inauguration of the STM led to the consolidation of the business under one roof, and some buyers from outside soon became traders and settled down in Surat. A revolving restaurant located atop the STM is a landmark, claiming to be “India’s first revolving restaurant”.

SILK CITY SURAT Today the Surat Textile Market is dominated by Marwadis, Jains, Sindhis, Punjabis and Haryanvis.

Silk city surat Surat’s textile markets

Silk city surat Surat’s textile markets are spread on both sides of Ring Road and the Saroli area. There are 221 textile markets housing over 80,000 shops and employing over 5.5 lakh people including labourers, accountants and salesmen. The Ring Road area is near the Surat railway station, as a result of which retailers from different parts of the country come to the city to buy sarees, dress materials and other textile items.

Arora recalls how he came to Surat with his father Sobharam for shopping. “I started doing business at the age of 15 years. I would accompany my father on his visits to Surat to purchase sarees,” he says.

Silk city surat“Morarji Desai had said in his speech that a day will come when the textile trading business, which is presently in the hands of Surati people, will be snatched away from the hands of Surati people by outsiders. Today, his words have come true. Very few traders are Suratis, while the markets are dominated by Marwadis, Jains, Haryanvis, Punjabis and Sindhis. There are 1,500 shops in the STM. The market was built by local Surati businessmen such as Himson Group, Vakhariya Group and two others. The purpose of building a market was to make all the traders available at one place for the benefit of buyers coming from other states,” says Arora.

Veterans of the industry recall how the textile business was done before the seventies.

Silk city surat Vakhariya, president of the South Gujarat Textile Processing Association, is 63 years old. He says, “My father Popatlal Vakhariya was running a textile business from our old home on Khangad Street in Salabatpura. There were handlooms and later power-looms for weaving grey cloth. Once the cloth gets ready it reaches dyeing and printing mills, from where it teaches the traders. There were around 30 dyeing and printing houses in Surat. But many weavers dyed grey cloth at their homes through “tapela dyeing”, in which a huge vessel containing colour and chemicals is heated with raw fabric kept inside. The buyers would land at the Surat railway station and reach adatiya (commission agents) at Salabatpura. The agents would bring them to our homes to buy sarees.”

Silk city surat Khatris, Ranas and Muslims now make up most of the population in Salabatpura in the Walled City area. The power-looms and handlooms were run at houses with family members involved in production. Male members dealt with customers and commission agents.

Vakhariya adds, “My father and others bought shops in the STM with an intention to expand the business and it did expand. We still have our shop in the STM. As our business grew, we started power-loom units and now run a dyeing and printing mill in Pandesara. We have expanded the business and are very much satisfied.”

Following the success of the STM, a few other markets like Bombay Market, 451 Market, Reshamwala Market were built by 1980. Later the business grew and many buyers coming from other states and commission agents aquired shops in these markets. “They bought houses, became residents of Surat and their children were born and brought up here,” says Jay Lal, a senior textile trader who hails from Haryana.

Earlier, buyers coming from other states trusted commission agents and bought sarees from houses by paying in cash. Over a decade and a half, the terms and conditions of payment have changed; now goods are sold on 90-day credit. And traders take back rejected or unsold goods.

Kailash Hakim, president of the Federation of Surat Textile Traders Association, says, “The textile industry of Surat has progressed a lot thanks to factors such as the easy availability of yarns, power-looms, dyeing and printing mills and labourers as well as the lack of union problems. Traders and buyers coming from outside both feel safe here…”

To attract customers, value additions are done on sarees and dress materials like embellishments, embroidery work and laces. Earlier, buyers from other states would come and check fabric, designs and colours and give orders. Nowadays, such details are shared on WhatsApp before orders are placed. Apart from this, e-commerce platforms have also helped expand the business in the market.

Silk city surat

Silk city surat Surat’s sarees and dress materials have the highest demand in Uttar Pradesh, Bihar, West Bengal and South Indian states. One factor behind the growth of Surat’s textile markets is the presence of all segments of the industry in the city. Manoj Agrawal, a former president of FOSTTA, says while the textile weaving industry is well established in Maharashtra, goods from there also land in Surat, because the neighbouring state does not have other segments of the industry

Silk city surat Whereas there were around nine textile transport firms during the seventies, over 225 such firms transport textile goods to other states. Yuvjraj Deshle, 59, president of the Surat Textile Goods Transport Association, says, “I joined the transport business in Surat in 1979 as a driver. We used to travel to different states to deliver textile parcels. On an average 35 trucks loaded with textile parcels would then leave for other states daily. Now over 230 trucks leave Surat daily with textile goods.”

Surat, India’s second largest city, is a major textile manufacturing hub and is known as the Silk City of India. The city’s textile industry is responsible for 40% of the country’s synthetic fabric production. Here are some things to know about Surat’s textile industry:

Silk city surat thttps://www.textileinfomedia.com/market/Silk-City-Textile-Market

- Production: Surat produces around 25 million meters of processed fabric and 30 million meters of raw fabric every day.

- Activities: Surat’s textile industry is involved in yarn production, weaving, processing, and embroidery.

- Markets: Surat’s main textile markets are India and other Asian countries.

- Brands: Famous brands like Garden and Vimal textiles originated in Surat.

- Adaptability: Surat is known for its ability to quickly adapt to the latest trends and changes.

- Sustainability: Surat’s textile industry is working to improve its manufacturing processes to be more eco-friendly. This includes using renewable energy, reducing the use of coal, electricity, and water, and following good practices for dealing with liquid effluents.

- The Textile Industry of Surat

The famous brands of Garden andVimal textiles evolved from Surat. A few other brands like Parag and Praffulfrom Surat did become famous for a short time, but failed to create a lastingimpression in the market

Majormarkets

The main market for Surat’stextile products are India and other Asian countries. Around 90% of polyesterused in India comes from Surat. However, international demand for its productsis not very significant. The Middle East is the major export market for Surat’stextile products. According to experts, more improvisation in the quality isrequired to cater to the demands of the international market.

Growth

The Surat textile industry hasgrown considerably over time. As per recent figures, textile production inSurat has grown by 10% in the last 5 years, while the market for embroidery hasgrown from an almost negligible amount to around Rs. 30000 million over the sameperiod.

Strengths

One of the main reasons behind thegrowth of Surat’s textile industry is the city’s ability to adapt to changesand the latest trends. The city is quick to respond to any changes in thepreferences of people. The industrialists here have strong entrepreneurialskills.

Challengesfaced

The Surat textile industry hasgone through quite a few setbacks as well.

Most of the traders have a fixed group of clients, with whom they trade. Most of the business is done on a credit basis. According to the Federation of Surat Textile Traders Association, the industry suffered a loss of Rs. 200 crores in the year 2004-05 on account of frauds by customers. The industry suffered a huge loss in the floods of 2006 as well. Around 40000 textile shops were damaged in Surat in these floods and the total loss was reported to be at Rs.10 crore per day. However, the city has always been quick to rise from these setbacks.

The rising cost of power and labour, which consequently raises the cost of production is another issue faced by the Surat textile industry. Most of the labour employed in this industry is unskilled and comes from various areas such as Bihar, Orissa, Maharashtra and Uttar Pradesh. The industry faces shortage of skilled labour. Moreover, severe labour crunch is felt by the industry during April-June when the laborers travel to their hometowns.

The government has set up institutes to train the laborers, but these institutes are not very well equipped. The lack of an international airport in Surat contributes to the low demand for its products in the international market.

It is also necessary to update the technology used in the industry as well as the infrastructure.

Conclusion

In spite of certain drawbacks, the city occupies a major position in the production of manmade fabrics. Around 65% of India’s manmade fabric production is done in Surat. The city expects a growth rate of 15-20% in manmade fabric demand in the near future. Hence, the future of the Surat textile industry does look bright.

To read more articles on Textile, Fashion, Apparel, Technology, Retail and General please visit https:/lifeeasy24.com /industry-article

To promote your company, product and services via promotional article, follow this link: https:/lifeeasy24.com/services/featrued-article/featured_article.asp

Recent Comments